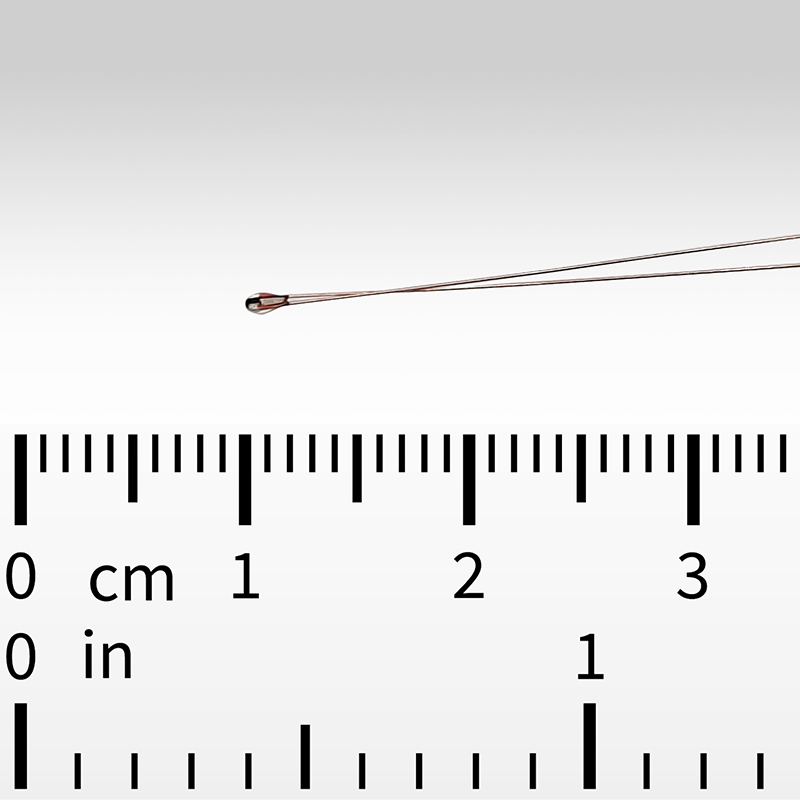

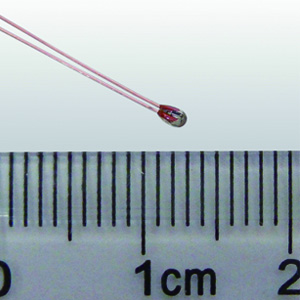

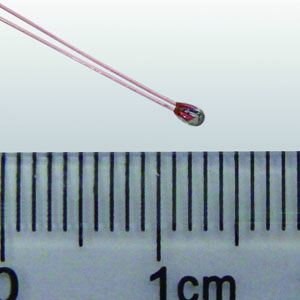

Glass Encapsulated NTC Thermistors ATH50KR8B3950K0.5%

FEATURES

APPLICATIONS

| Part Number | STOCK | 5-9PCs | 10-49PCs | 50-199 PCs | 200-499 PCs | ≥500 PCs | Buy Now | Datasheet | Add TO WATCHLIST |

|---|---|---|---|---|---|---|---|---|---|

| AATH50KR8B3950K0.5% | 390 | $3.00 | $2.80 | $2.60 | $2.40 | $2.20 |   |  |

One common issue encountered when potting the thermistor into a solid object to sense its temperature is the formation of air bubbles within the epoxy between the thermistor bead and the target object. These air bubbles can significantly delay the thermistor's response time. To address this problem, it is recommended to drill a deep counterbore hole and use thermal conductive epoxy to pot the thermistor at the bottom of the hole. This method effectively reduces the formation of air bubbles and enhances the thermistor's overall performance. To prevent the formation of air bubbles during the potting process, it is recommended to cure the epoxy at the temperature specified by the manufacturer. For optimal results, curing should be conducted in a vacuum environment and/or on top of a vibration platform to eliminate any remaining air pockets. By taking these measures, the potting process can be optimized, resulting in accurate temperature sensing with the shortest possible response time.