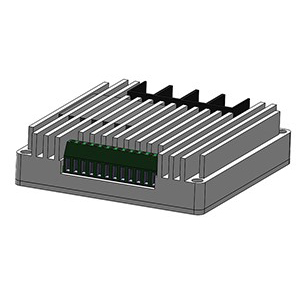

CPU of computer is a high density heating element. Based on the cooling principle of thermoelectric cooler (TEC), the cold end of TEC is in contact with the display chip and the hot end is in contact with the heat sink. When connecting a power supply, the temperature difference of the cold and hot end will come out and moves from the cold end to the hot end through lattice energy. Only if the hot end heat can be dissipated effectively, the cold end will be cooling constantly and the cooling effect will be pretty good. In fact, TEC is a heat pump, which can transfer the heat from chips to heat sinks, so only if the heat of the TEC hot end is being dissipated continually, the cold end can be cooling and the display chips can be in a relatively constant temperature state. However, in the hot end of TEC, the heat sink and fan are still needed. In the process of using TEC, there are some other points to consider.

(more)